A monoblock forged wheel is a type of high-performance wheel that is made by forging a single piece of metal. The term "monoblock" means that the wheel is made from a single piece of material, which is typically aluminum alloy 6061-T6.

The forging process for Monoblock Custom Forged Wheels involves applying high pressure and heat to the raw material, which results in a denser and stronger wheel compared to cast wheels. Monoblock forged wheels are known for their high strength-to-weight ratio, which allows them to be lightweight yet extremely durable.

These custom forged monoblock wheels are often used in high-performance cars and sports cars due to their ability to handle high speeds and provide better handling and performance. They are also popular in the aftermarket scene because they are customizable and can be made to fit a variety of vehicle applications.

Car Wheels provides customized forged wheels with elegant designs in personalized fitments. No matter in monoblock / 2-piece / 3-piece, rims from Car Wheels are meant to fulfill the needs for every car owner to build up their auto-fantasy.

Car Wheels has so many styles and customization options that if you can dream of it, we can make it.

We ship the wheels directly from the factories to your front door. By this way, we could offer the best price to customers.

Forged monoblock wheels are machined from only the highest quality forged 6061-T6 aluminum creating a wheel that is not only strong but stiff and lightweight.

Forged monoblock wheels are designed and machined with optimal performance in mind to not only reduce overall weight but still retain integral strength.

Forged monoblock wheels are offered in a vast array of powder coated finishes. All wheels are held to the highest standards of finish quality.

Every forged wheel is custom made-to-order for each individual customer and each unique vehicle application. This extremely resource-intensive manufacturing process ensures that every order is individually engineered, precision machined, hand finished, and custom powder coated to deliver a perfect vehicle fitment and to fulfill each customer's personal creative vision.

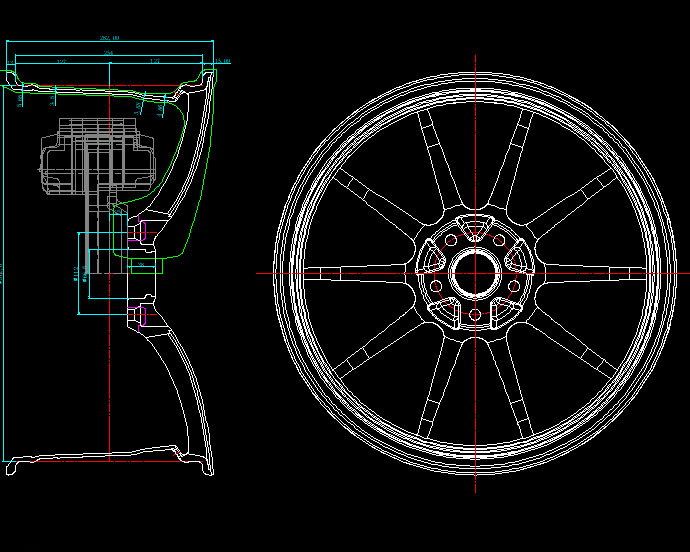

CAD software to design wheels, Every design will pass through multiple drafts until the look is perfect.

Concavity or dish depth is optimized as per client's request. Brake clearance will also be verified.

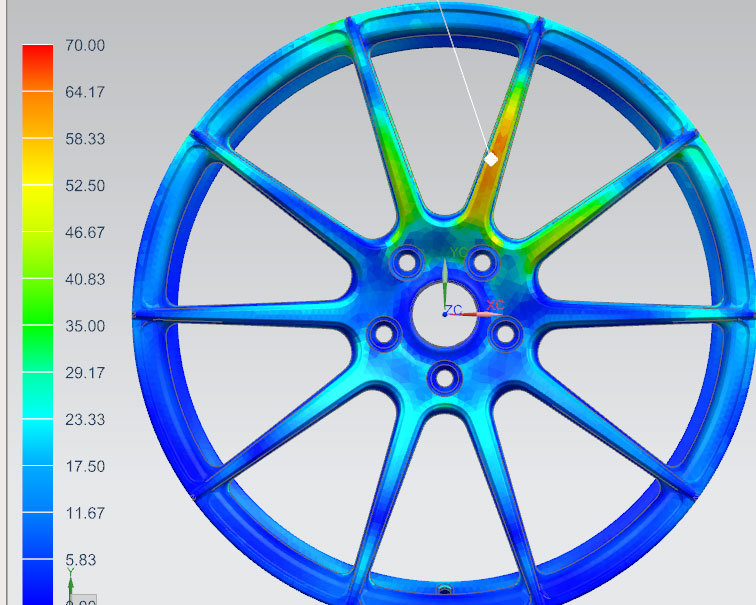

Before production, the designer will perform computer simulation tests - Finite Element Analysis.

CNC machines to manufacture wheels After client confirmed all the drawings, it takes about 30 days to manufacture

he Hand Prep Department is responsible for prepping the wheel for its final surface finish.

Manufacturing facilities include a wide array of finishing options

competent shipping partners