Two-piece wheels refer to wheels that consist of two separate parts: the outer barrel and the center section. The outer barrel is usually made of aluminum and is responsible for holding the tire in place, while the center section is made of either aluminum or steel and is responsible for mounting the wheel to the vehicle hub.

Two-piece wheels offer several benefits over one-piece wheels. For one, they are generally lighter in weight, which can improve vehicle handling and acceleration. They also allow for greater flexibility in wheel sizing and fitment, as the two pieces can be bolted together in different configurations to achieve different offsets and widths.

However, it's worth noting that two-piece wheels are generally more expensive than one-piece wheels, and they can be more difficult to repair in the event of damage. Additionally, they may require more maintenance, as the bolts that hold the two pieces together must be periodically checked and tightened to ensure a secure fit.

2 piece wheels are designed to bring you a huge level of customization to get the perfect look and fitment for your car. Each design will be custom made to order allowing you to choose from a range of options such as: Diameter, Width, Offset, Barrel Finish, Face Finish, Hardware Color.

Car Wheels provides customized forged wheels with elegant designs in personalized fitments. No matter in monoblock / 2-piece / 3-piece, wheel rims from Car Wheels are meant to fulfill the needs for every car owner to build up their auto-fantasy.

We are now a full fledged design and production solution provider, catering to the needs of the premium aftermarket wheel companies.

Innovative automotive wheel development & design company. The core team consist of professionals in industrial design, production technology management, marketing strategy and management etc., who have more than 15 years of experience in the wheel industry.

Every forged wheel is custom made-to-order for each individual customer and each unique vehicle application. This extremely resource-intensive manufacturing process ensures that every order is individually engineered, precision machined, hand finished, and custom powder coated to deliver a perfect vehicle fitment and to fulfill each customer's personal creative vision.

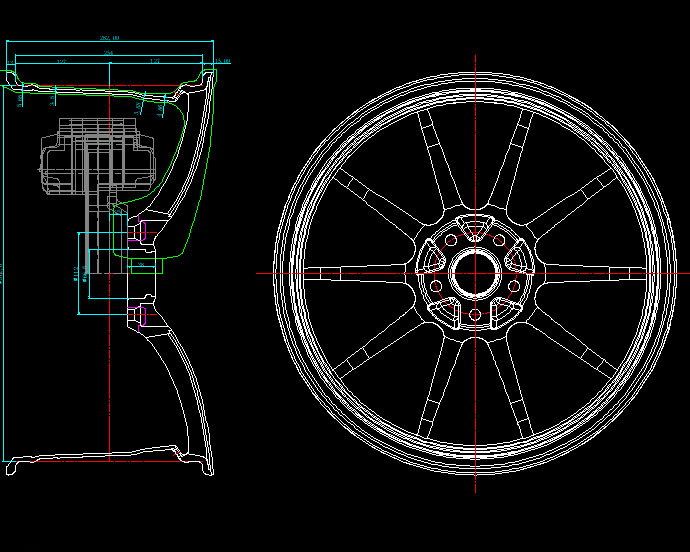

CAD software to design wheels, Every design will pass through multiple drafts until the look is perfect.

Concavity or dish depth is optimized as per client's request. Brake clearance will also be verified.

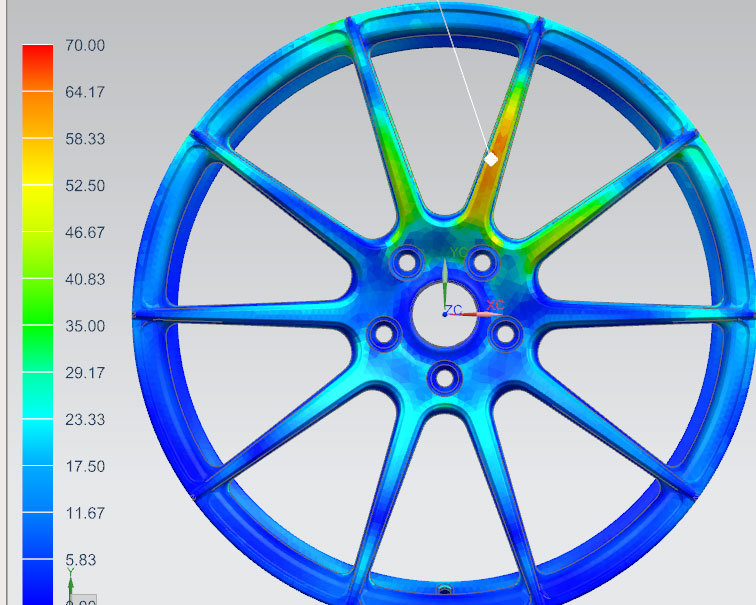

Before production, the designer will perform computer simulation tests - Finite Element Analysis.

CNC machines to manufacture wheels After client confirmed all the drawings, it takes about 30 days to manufacture

he Hand Prep Department is responsible for prepping the wheel for its final surface finish.

Manufacturing facilities include a wide array of finishing options

competent shipping partners