Custom car wheel rims forged are high-performance wheels that are made using a forging process. In this process, a solid block of metal is heated and then pressed and shaped into the desired wheel design using a high-pressure hydraulic press. This results in a wheel that is stronger, more durable, and lighter than traditional cast wheels.

Custom car wheel rims monoblock forged and 2 piece forged wheels are often used by performance enthusiasts who want to improve their vehicle's handling and performance. The custom forged wheels are known for their strength and ability to withstand high stresses and loads, making them ideal for high-performance driving.

One of the key benefits of custom car wheel rims forged is their ability to be customized to the owner's specifications. This means that the wheels can be designed to fit specific vehicle models and sizes, as well as to match the owner's desired aesthetic.

Overall, custom car wheel rims forged offer a unique combination of strength, durability, and customization options that make them a popular choice among car enthusiasts who demand the best performance from their vehicles.

2-Piece Wheels

2-piece forged wheels consist of two separate components: the barrel (the rim) and the face (center piece and spokes). 2-piece wheels offer more customization and a wide variety of offset and width options.

> Made from either a cast aluminum center welded to a forged aluminum barrel, or a forged aluminum center welded to a forged aluminum barrel.

> This construction allows for the flexibility of custom sizes, widths, backspacing, and finishes.

> These wheels are custom made to order to the exact specifications needed for modified vehicles.

> 2-Piece wheels can be custom finished in almost any color combo desired.

> Perfect for those with extensive suspension and/or body modifications or those that want the largest and/or widest wheel and tire package possible.

> 2-piece wheels have added benefits regarding repairs: unlike 1-piece, the barrel or the face of the wheel can be replaced independently of each other.

One Piece Monoblock Wheels

1-piece wheels are the most common wheel types you encounter on the road. 1-piece wheels are just that: one singular piece of metal - manufactured by casting molten aluminum into a mold. Some key elements of running 1-piece wheels include:

> 1-Piece wheels have a set size and backspace.

> Perfect for those with stock or mildly modified vehicles that aren't interested in maximizing their wheel/tire package.

> Lower replacement cost

> Mass produced, stocked in warehouses country wide, and available for immediate delivery.

> Made from either a cast alloy center welded to a forged alloy barrel, or a forged alloy center welded to a forged alloy barrel.

Overall, custom car wheel rims forged offer a unique combination of strength, durability, and customization options that make them a popular choice among car enthusiasts who demand the best performance from their vehicles.

Innovative automotive wheel development & design company. The core team consist of professionals in industrial design, production technology management, marketing strategy and management etc., who have more than 15 years of experience in the wheel industry.

Every forged wheel is custom made-to-order for each individual customer and each unique vehicle application. This extremely resource-intensive manufacturing process ensures that every order is individually engineered, precision machined, hand finished, and custom powder coated to deliver a perfect vehicle fitment and to fulfill each customer's personal creative vision.

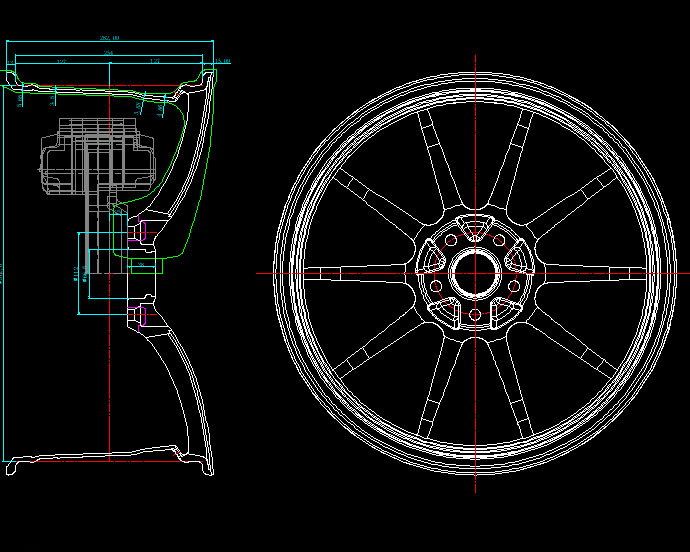

CAD software to design wheels, Every design will pass through multiple drafts until the look is perfect.

Concavity or dish depth is optimized as per client's request. Brake clearance will also be verified.

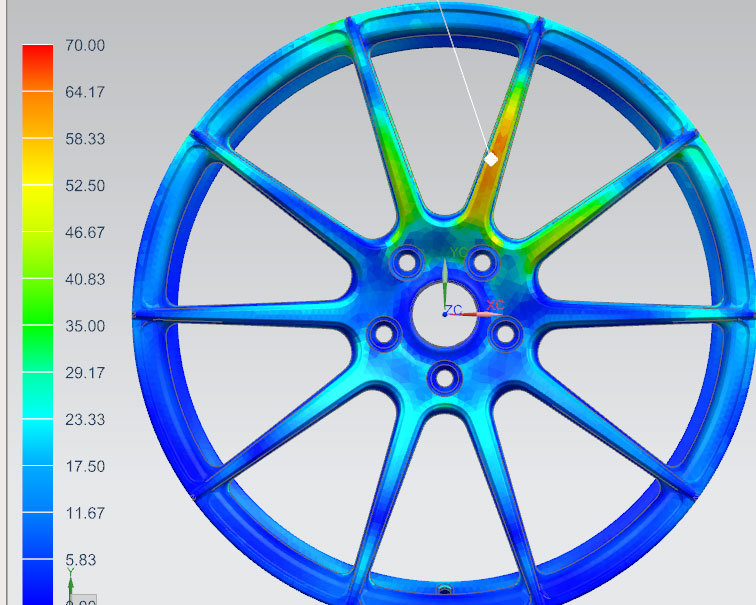

Before production, the designer will perform computer simulation tests - Finite Element Analysis.

CNC machines to manufacture wheels After client confirmed all the drawings, it takes about 30 days to manufacture

he Hand Prep Department is responsible for prepping the wheel for its final surface finish.

Manufacturing facilities include a wide array of finishing options

competent shipping partners